PCB assembly guidance in manufacturing

Our customer is an international design and manufacturing company with over 50 years of experience in designing, building and delivering technology innovation, supply chain and manufacturing solutions. They are active in many industries such as automotive, healthcare and communications. With a presence across 30 countries, they employ over 150 000 people.

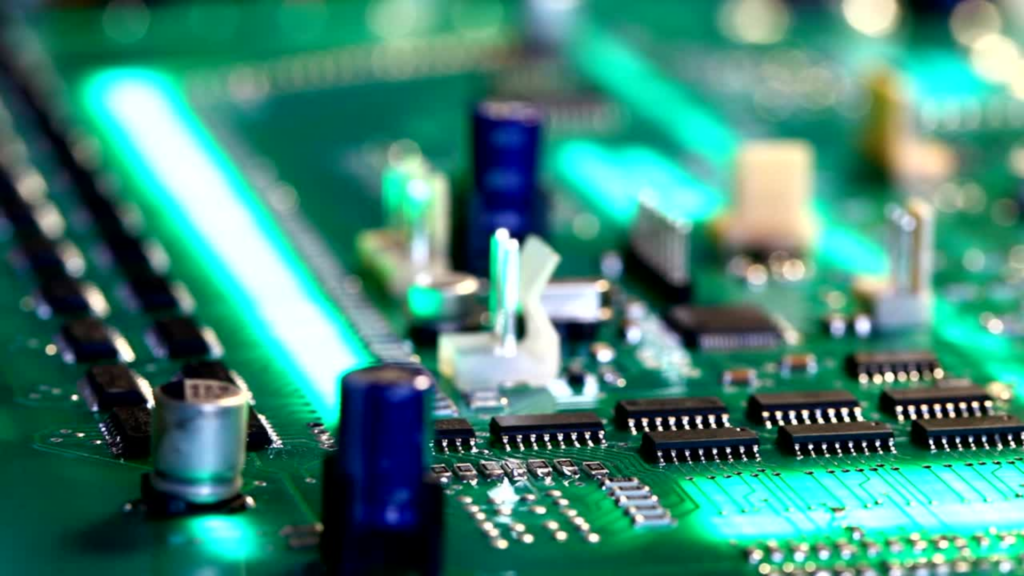

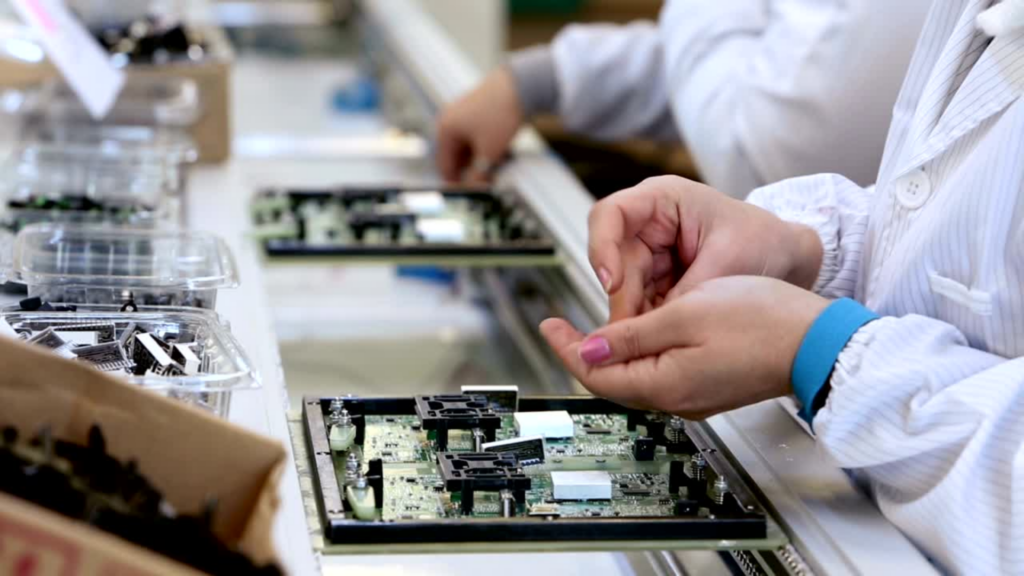

The Arkite Operator Guidance Platform was implemented in the context of a PCB Assembly project. In this project, operators are presented with a pallet of four circuit boards at their workstation on a conveyor belt. The pallet is put at a fixed location on the conveyor belt using an automatic stopping system. The operators have to mount a large number of SMD components, such as resistors and capacitors, onto each of these circuit boards with. When they are done, the stops on the conveyor belt are lowered and the operators push the pallet to the next workstation. There, the components are soldered automatically.

Our customer struggled with a considerable scrap and rework rate due to human errors. Operators did not work in a standardized way. Often they took several components in their hands at the same time, and mounted them on any of the four circuit boards in a random order. As a result, operators often dropped components, letting them slip between the rollers of the conveyor belt. Other components were mounted at the wrong place, or forgotten and therefore not placed at all.

Therefore, our client was looking for a way to standardize the assembly process, imposing a fixed order to the operators for picking the components and assembling the circuit boards. They decided to evaluate by means of a pilot project on workstation whether the Arkite Operator Guidance Platform was able to give an answer to their needs.

The Arkite Operator Guidance Platform was installed above the workstation on the conveyor belt. Using Arkite’s Distance Calculator, the optimal height was defined based on the surface of the working area that needed to be detected. The workstation was also equipped with a touch screen. We were able to configure the entire assembly process in our software remotely before the installation, based on station instruction cards. This allowed for a minimal production downtime of the station during installation. The mounting of the sensors and projectors, the installation of the touch screen as well as the custom mapping adjustments could be finalized within 8 hours.

The Arkite Operator Guidance Platform was installed above the workstation on the conveyor belt. Using Arkite’s Distance Calculator, the optimal height was defined based on the surface of the working area that needed to be detected. The workstation was also equipped with a touch screen. We were able to configure the entire assembly process in our software remotely before the installation, based on station instruction cards. This allowed for a minimal production downtime of the station during installation. The mounting of the sensors and projectors, the installation of the touch screen as well as the custom mapping adjustments could be finalized within 8 hours.

The Arkite Operator Guidance Platform was also integrated with our client’s barcode scanner interfaced MES system and with the conveyor belt’s automatic stopping system.

Once the Arkite Operator Guidance Platform was installed, it guided the operator step by step through the relevant assembly process:

- At the start of his shift, the operator selects the assembly process he needs to perform that day on the touch screen;

Note

If required, the operator can select a different assembly process at every moment during his shift.

- When the Arkite Operator Guidance Platform detects the arrival of the pallet with the PCB’s on the conveyor belt, it automatically starts the assembly process guidance;

- In each step of the process, the relevant area on the conveyor belt or the picking bin containing the component to assemble is highlighted using a light projection;

- With a hand scanner, the operator scans the component to assemble – the Arkite Operator Guidance Platform forwards this information to the MES system.

- On the touch screen, the action that needs to be executed is described, both in text and by image instructions;

- The 3D sensor, mounted above the workstation, monitors and validates whether an operation has been performed correctly – the smallest validation area was 20×20 mm;

- Only after successful validation, the operator can continue with the next step

This way, the Arkite Operator Guidance Platform ensures that every part is assembled in the correct way;

- On the touch screen, the progress of the total assembly is indicated

This way, the Arkite Operator Guidance Platform ensures that not a single part is forgotten during the assembly=

- Once the assembly process has been completed, the platform sends a message to the automatic stopping system and the stops on the conveyor belt are lowered;

- The operator pushes the finalized PCB to the next station;

- When the Arkite Operator Guidance Platform detects the arrival of the next pallet, it automatically restarts the process guidance.

The Arkite Operator Guidance Platform also takes the experience level of the operator into account. New operators get additional

instructions and guidance, while for more experienced operators the guidance is limited to the essentials. This way, experienced operators are not slowed down by our platform, while novice operators get sufficient guidance to work independently without the need for constant supervision.

During the assembly process, the Arkite Operator Guidance Platform registers and logs a wide array of data regarding cycle times, step duration times, errors, anomalies and system status.

This information is reflected in real-time in the system’s reporting module, and allows the shift supervisor to continuously monitor the assembly process and intervene if necessary.

Furthermore, all data are transmitted to a server from where the information can be processed, for example with Excel or BI, for further analysis. This provides process engineers with valuable input for process optimization.

The table below shows the official results from the monthly quality report generated by our client’s Quality Inspection department, one month after installation of the Arkite Operator Guidance Platform.

| Area of improvement | Before installation of the Arkite Operator Guidance Platform |

1 month after installation of the Arkite Operator Guidance Platform |

Improvement in % |

| Productivity

(average station takt time) |

100 seconds | 93 seconds | 7% |

| Error rate (in %) | 0,12% | 0% | 100% |

| Rework and scrap rate (in %) | 0,31% | 0,11% | 64% |

| Training time (in hours) | 2-4 hours

(depending on assembly complexity) |

1-2 hours

(depending on assembly complexity) |

50% |

Note

From experience with other clients in the same industry, a further improvement can be anticipated in the upcoming months, mainly in the area of productivity.

Want to know more?

Are you curious about what Arkite’s HIM can do for your organization?

- Visit our website to learn more about our product and customer references

- Request a free live demo

- To know more about the technology used by the HIM, navigate to http://documentation.arkite.com and download our FAQ and Technical Information