ARKITE OPERATOR GUIDANCE PLATFORM.

Arkite Platform

Arkite licenses can be combined for optimal efficiency, quality and flexibility:

- ● Arkite GUIDE: Delivers AR work instructions, making complex tasks more intuitive.

- ● Arkite VALIDATE: Enhances operations with real-time operator validation to reduce errors.

- ● Arkite VISION: Adds product inspection capabilities for advanced quality control.

Production Activities

Arkite’s platform enhances manufacturing processes with AR solutions in production:

- ● Picking & Kitting: Uses Pick-by-Projection for clear material bin indication with validation.

- ● Assembly: Provides AR Work Instructions during manual assembly.

- ● Packaging: Provides dynamic projections for an optimized capacity.

Arkite Features

- ● Digital Work Instructions: Displayed on the workbench using Projected AR.

- ● 3D Sensor Validation: Ensures operator activity checks and process validation.

- ● Arkite Vision Sensor: Inspects the quality of your product.

Process Engineering

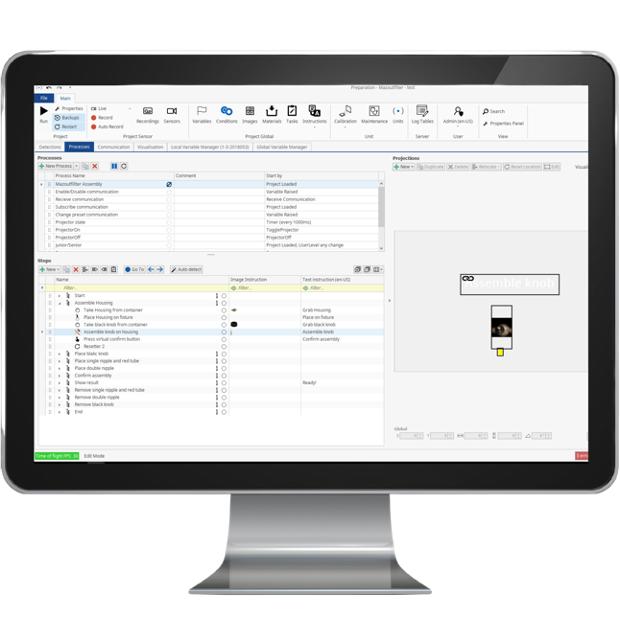

Arkite optimizes process engineering with seamless instructions, intuitive configuration, and integration.

- ● Workflow Manager: Easy access and instant updates of work instructions on all workstations.

- ● User-Friendly: Fast and intuitive creation of work instructions and project configuration.

- ● Flexible Integration: Support of a range of communication protocols.

Process Improvements

Arkite’s data logging enables detailed traceability and analytics to increase productivity and quality.

- ● Increased Efficiency: Streamlines workflows, boosting productivity with fewer delays.

- ● Quality Assurance: Improves operations through identification of production errors.

- ● Insightful Analytics: Provides data-driven insights for process improvements.

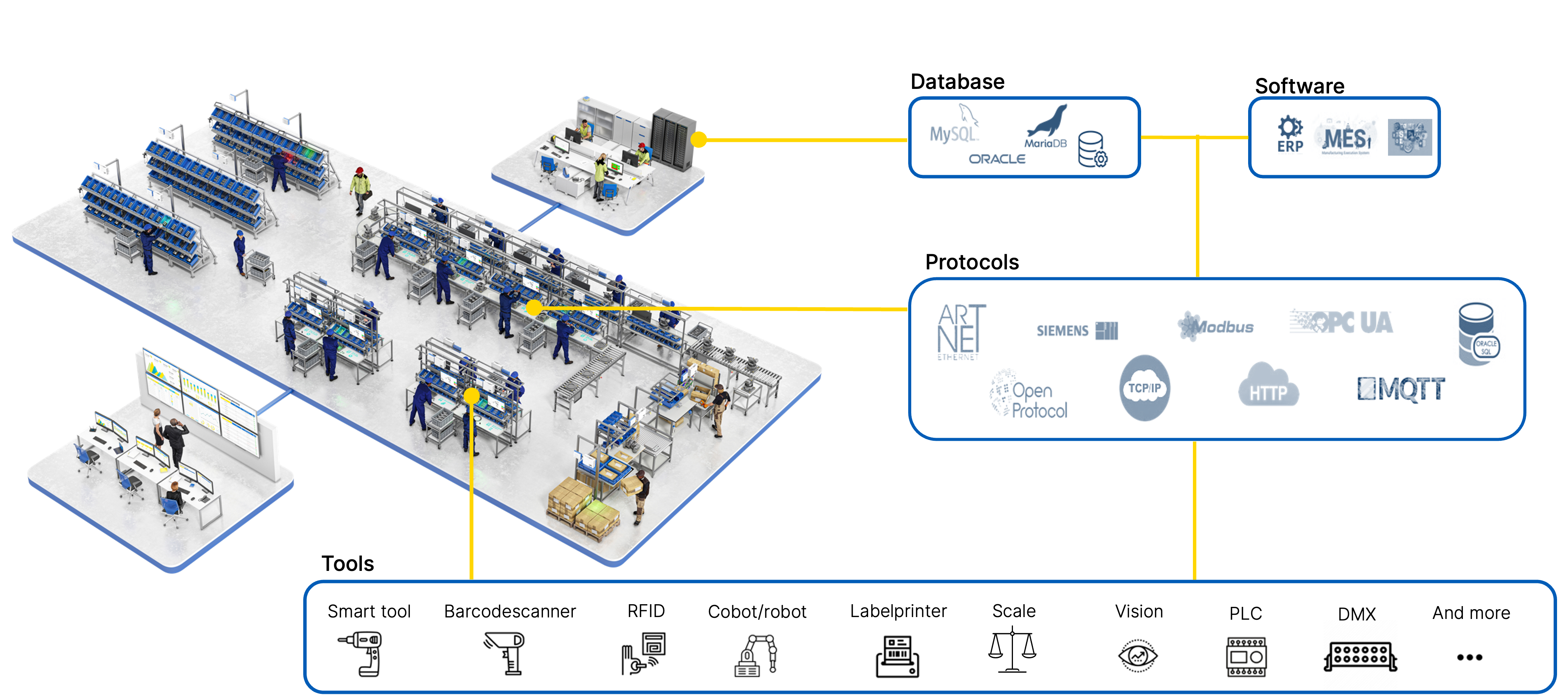

Integrating our platform into your ecosystem

Arkite’s Operator Guidance Platform comes with a flexible Application Programming Interface (API) that allows swift communication with other applications in your software ecosystem, like MES and ERP systems.

Furthermore, a wide variety of communication protocols are supported, enabling the system to communicate to external devices.

Easy-to-use software

Arkite Software transforms the manufacturing landscape with its innovative augmented reality (AR) platform, making complex work instructions simple and intuitive. Designed for effortless integration and use, it ensures seamless operations and enhanced productivity without the need for coding expertise.

- Streamlined creation of digital work instructions: quickly and effortessly design detailed work instructions by adding text, images, videos, GIF’s, icons etc to your workstations.

- Rapid onboarding: Get up and running with just 2 days of training, making technology adoption swift and straightforward.

- No coding required: Create and implement work instructions without any programming knowledge, making the system accessible to all.

- Effortless version control: Manage and update instructions with built-in versioning, ensuring no project data will be lost.

Integrated Smart Vision

Sometimes, it is not enough to ensure your operators execute your assembly process in the correct sequence. You need to have absolute certainty that each and every small component is effectively placed at the right location and in exactly the right position with the correct orientation.

If you choose the Arkite platform with a Vision license, an additional high definition infrared vision sensor is included. You can then benefit from Arkite’s smart vision features:

- Product inspection during assembly

- Improved presence detection for small objects (> 0,5 cm)

- Object orientation

- Tool tracking

Arkite’s smart vision features are fully integrated in the Arkite software and can be used without needing any programming knowledge.

With our brand new Arkite VISION license, an additional high definition vision sensor is added into the Arkite platform.

Digital Work Instructions

It might be pretty easy to break down your assembly process in detailed working procedures, but implementing those procedures on the shop floor can be a real challenge. Operators do not have the time to consult lengthy manuals as any interruption slows down the assembly process. Furthermore, procedures need to be kept up-to-date at all times. And last but not least, there is no way to ensure your operators actually follow your procedures.

With Arkite, you can provide your operators with just-in-time digital work instructions. Instructions can be created as text, image or video and are displayed at the exact time they are required in the assembly process. Digital work instructions allow you to standardize your assembly process and get rid of printed procedures and manuals. This way, you give your operators the support they need, without suppressing their independence.

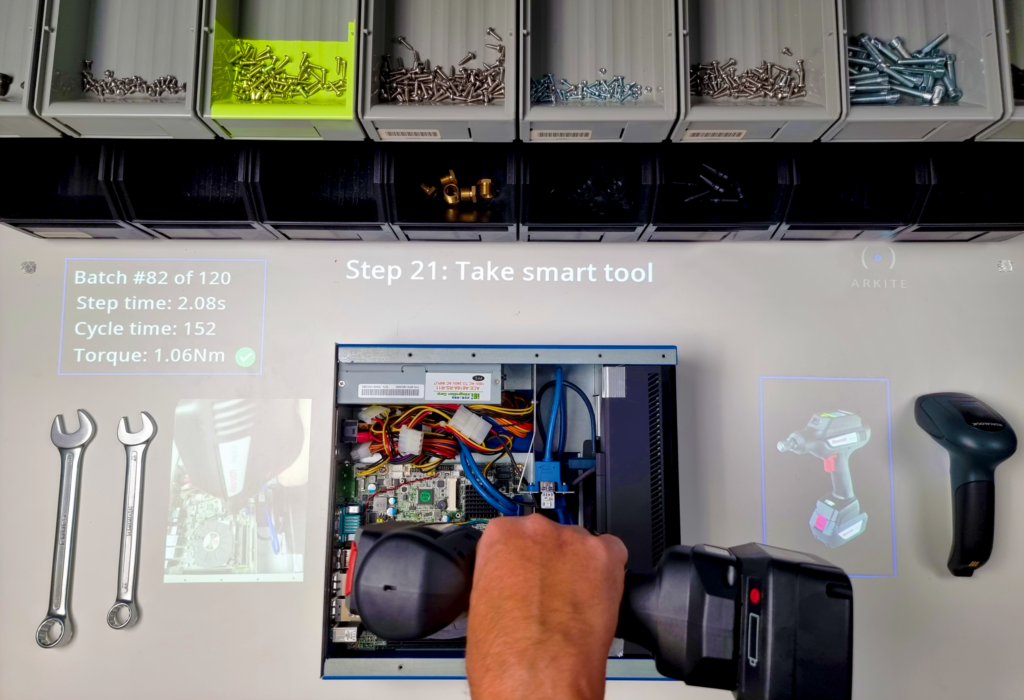

Projected Augmented Reality (AR)

For an efficient, standardized and error free assembly process, it is of key importance operators have access to relevant work instructions at the right time. Therefore, you don’t want your work instructions to be in a separate system. You want them to be seamlessly integrated into your work environment. This way, they can easily be linked to your assembly process and made available at the correct time and place to your operators.

Arkite enriches the physical workbench with a digital overlay. By means of a projector, it highlights the relevant work area and projects related text, image and video instructions. Projected Augmented Reality provides your operators with a hands-free user experience. And contrary to AR wearables such as glasses or headsets, they will not experience the platform as uncomfortable to use during a complete working day. Therefore, Projected Augmented Reality is the best option to go with in most industrial use cases.

3D Sensor Validation

Providing your operators with the correct instructions is one thing. Enforcing them is an even bigger challenge. How can you make sure operating procedures are executed correctly without putting a supervisor next to every workstation? How can you warn your operators when they are about to make an error?

Arkite’s time-of-flight sensor captures data by sending out infrared light beams and uses those data to create a 3D image of the workbench. It verifies the presence of all components and tools at their expected location. It also validates whether all required actions in the assembly process are executed correctly and in the right sequence. Therefore, Arkite’s 3D sensor validation represents a critical opportunity for quality improvement compared to current practices.

Integrated Smart Vision

Sometimes, it is not enough to ensure your operators execute your assembly process in the correct sequence. You need to have absolute certainty that each and every small component is effectively placed at the right location and in exactly the right position with the correct orientation.

If you choose the Arkite platform with a Vision license, an additional high definition infrared vision sensor is included. You can then benefit from Arkite’s smart vision features:

- Product inspection during assembly

- Improved presence detection for small objects (> 0,5 cm)

- Object orientation

- Tool tracking

Arkite’s smart vision features are fully integrated in the Arkite software and can be used without needing any programming knowledge.

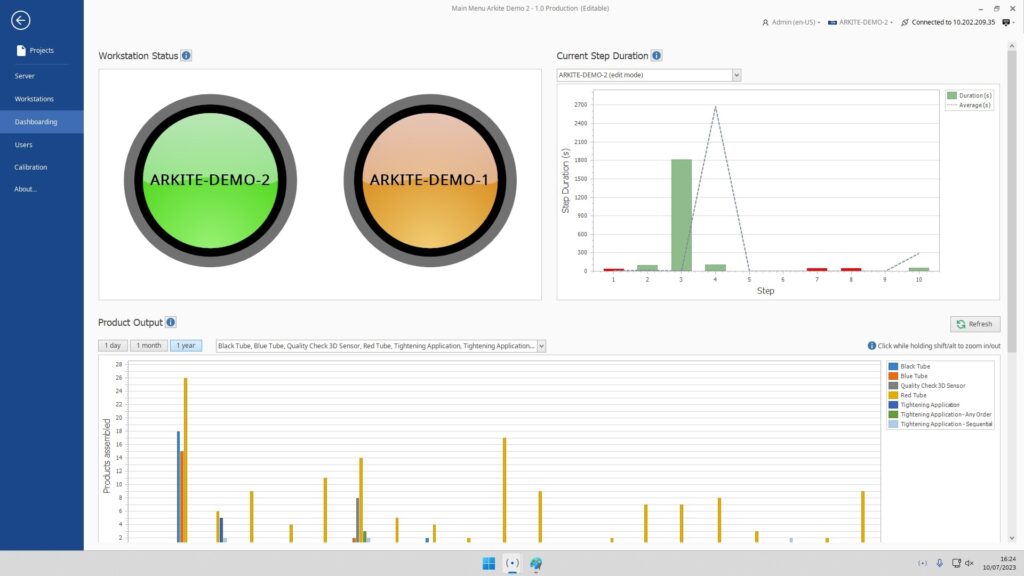

Dashboarding

“To measure is to know”, as Lord Kelvin famously said. It is impossible to improve your production process if you don’t know where mistakes are made, which steps take longer than expected and at which workstations (most) issues are experienced.

Dashboarding provides you with insights on various aspects of your assembly process and the status of your system thanks to a graphical representation of data. In the Arkite software, a set of dashboards is included by default. Additionally, you can easily create your own dashboards in a dedicated tool (like PowerBI) using the extensive data that is logged by the Arkite software.

CAD/CAM support

Products in the manufacturing industry are often designed in a CAD model.

Arkite allows for the projection of CAD drawings in True Scale (1:1). Furthermore, you can also design your digital workbench based on a CAD model. When doing so, the size and location of all components used in your assembly process are defined by both a 3D model (.STL file) and a transformation matrix that positions the CAD model in space. Such a transformation is typically provided by the CAD/CAM system.

Pick-by-Light with DMX

With our DMX communication module, you can connect DMX lights through an Enttec Open DMX USB interface (SKU 70303). This allows you to implement pick-by-light operator guidance instead of projections.

This is of particular interest in use cases with large picking containers or picking containers that are arranged in a larger area that can not be covered with a limited number of projectors.

Security, Maintainability and Data Integrity

Providing your operators with clear work instructions is one thing, maintaining those work instructions proves to be an even bigger challenge as you want to make sure operators don’t use outdated procedures. Furthermore, you need to be absolutely sure that your product data and assembly practices are kept confidential.

The Arkite software is split in a workstation and a server component. All data and resources for multiple clients and projects are stored centrally on a separate system. In this way, a high level of security, maintainability and data integrity can be obtained. In case of a hardware issue at one of your workstations, all required data can be easily retrieved from the server.

Since all Arkite projects are stored on the server, they can be accessed and modified remotely. This allows you to update work instructions from your desk, while production on your workstations can continue – no downtime is required. Once you have finished, the updated work instructions are instantly available on all workstations.

Multi-Variant to support flexible production

In all manufacturing industries, flexibility is a key factor to be competitive. Do you also face challenges to fulfill your clients’ expectations regarding just-in-time delivery of different products and product variants in different batch sizes? This can quickly become a logistic nightmare, and put a lot of stress on your operators who need to be very attentive not to mix up different assembly procedures. Mistakes are easily made, leading to scrap and production delay. A lot of training is required to keep personnel sufficiently skilled and up-to-date.

Arkite can help you in solving these challenges. After selecting the product that needs to be assembled, for example by scanning a barcode, it presents the operator with specific instructions for the selected product. The operator can be confident he is doing the right thing and errors can be prevented.

Arkite also deals with the configuration of product variants (or flavors) in a unique way. Arkite’s Variants feature allows you to efficiently cater for those different variants within the same assembly process. It allows you to indicate which steps are common and which steps should only be executed for specific variant(s).

Multi-Language

One of the main challenges many companies in the manufacturing industry face these days is the hiring of skilled operators. Unemployment rates are historically low, and there is a harsh competition among employers to bring in the best candidates. For operators that do have the required skillset, language can be an important obstacle. With limited command of the language, communication and understanding complex assembly processes is a major issue. Training takes a lot longer.

Arkite offers you an answer to these challenges. In our system, instructions can be configured in any language. With a single action, for example by pressing a virtual button on the workbench or by scanning a staff badge, the operator’s mother tongue can be selected and instructions are provided in his own language.

Click here to learn more about how Arkite can help you face the challenges of recruiting on a saturated labour market.

Integrated Smart Tools

In many assemblies, the proper tightening of screws, nuts, and bolts is crucial. To ensure this, smart tools are often used. Smart tools are tools that can communicate with external systems, and for example provide feedback about the torque that has been reached.

The Arkite platform can connect to smart tools over Open Protocol, Ethernet or Modbus. This allows you to configure them in such a way that they can only be used at a specific location during the correct step in the assembly process. At all other locations and times, the tool will be disabled. You will also be able to automatically set the desired torque at any point in your process. An operator will only be able to proceed with the assembly when the required torque has been reached.

Supported communication protocols

You probably already have a lot of tools and systems in place that support you during your manufacturing activities. Are you worrying about introducing yet another system? There is no need for that. Thanks to a wide variety of communication modules, the Arkite platform can be seamlessly integrated with your existing eco-system. Therefore, we support the communication protocols below:

• Barcode / QR Code scanners (over USB)

• Ethernet (TCP/IP)

• COM (serial port)

• Database (MySQL, oracle, ms sql, sqlite)

• DMX lights (through an Enttec Open DMX USB interface – SKU 70303)

• HTTP (web services)

• Modbus

• MQTT

• OPC

• Open Protocol (smart tooling)

• S7 PLC

• Epson Label Printer

We also have a flexible Application Programming Interface (API), supporting swift communication with MES and ERP systems.

This API can be used to push data from MES into the Arkite software in order to enable the on-demand flexible production. This integration will avoid stock pile-up and can benefit from the fact that the Arkite software is flexible to be programmed to deal with product variants on the fly.

Approval Process and Version Management

Do you work in a highly controlled industry? Do your operating procedures and work instructions need to be reviewed and approved by different levels in your organization before they can be moved to production? Do you need absolute certainty about the version of a procedure that was applicable at the time of a production issue?

Arkite’s Version Management feature allows you to setup a review and (optionally) approval process for your projects. The Arkite software keeps a version history of all your projects. In case of issues, an earlier version can easily be retrieved, consulted and restored.

Operator Experience Customization

Do you feel you are in need of a system that enforces your standard operating procedures? But do you also fear negative reactions from your staff? Indeed, there can indeed arise some resistance among operators against a system they experience as controlling and intrusive. Experienced operators sometimes feel they know what they’re doing and think instructions will only slow them down.

Arkite is very aware of these concerns and goes to great lengths to make sure the Arkite platform supports operators rather than confining them. Therefore, we developed the Experience level functionality. This feature allows you to further customize your project by changing the system behavior based on the operator’s level of experience. Depending on the experience level, you can decide to show additional instructions to novice operators and omit some instructions for experts. You can also adjust the pace of the assembly process. The experience level can either be set manually or it can be defined by the Arkite software, based on learning calculations.

Click here to learn about why we think digital work instructions and operator independence can go hand in hand.

Detailed explanation about our platforms features

Do you need some more information? Don’t hesitate to contact us!

Choose the plan that fits your use case

| Our plans | Arkite GUIDE |

Arkite VALIDATE |

Arkite VISION |

|---|---|---|---|

| Projected work instructions (text, image, video) | |||

| Pick-to-projection support | |||

| Operator activity validation | |||

| Object orientation | |||

| Object presence detection | |||

| Product inspection | |||

| Smart tool integration | |||

| Tool detection | |||

| Production data | Basic | Advanced | Advanced |

| Project versioning | |||

| CAD/CAM support | |||

| Operator experience level | |||

| Multi-language support |

Improve your

manual operations

with better

consistency

and reliability

%

error reduction

%

rework reduction

%

reduce training time

Customers already using our Arkite platform