Standardised work.

Maintaining standardised operations

- Step-by-step instructions through projected Augmented REality

- Safeguarding correct execution through 3D sensor validation

- Elimination of human errors

- Boosting process efficiency

Safeguarding the Standard

By defining a standard way of working, we secure a stable output while providing a foundation from which the production process can be further improved. Therefore, standardized work is the first and essential step to boost performance and quality as it establishes a baseline for comparison and allows to highlight problems and gaps that we can subsequently seek to close.

A standard operating procedure (SOP) is a set of written instructions that describes the step-by-step process that must be carried out to properly perform a routine activity. Standard operating procedures provide the policies, processes and standards needed for the organization to succeed. They can beneficial for a business by reducing errors, increasing efficiencies and profitability, creating a safe work environment and producing guidelines for resolving issues and overcoming obstacles. It ensures safety, correctness and efficiency, and makes sure we have the best work method and quality, with the least amount of waste at the lowest cost.

Manufacturers are often challenged to secure that the standard is widely applied and effectively used in their operations. As a result, too many errors occur in operations due to operators not following the SOPs consistently. There are many reasons why SOPs are not followed: lack of adequate training, misinterpretation of the written documentation, out-of-date or missing information or the use of wrong SOPs corresponding to a certain product variant.

By introducing the Arkite Operator Guidance platform, manufacturers are able to maintain (or even return to) the standard into their operations. The combination of the Arkite Augmented Reality instructions with the validation by the Arkite 3D sensor ensures that operators are guided through the SOPs in a safe, efficient and resilient way.

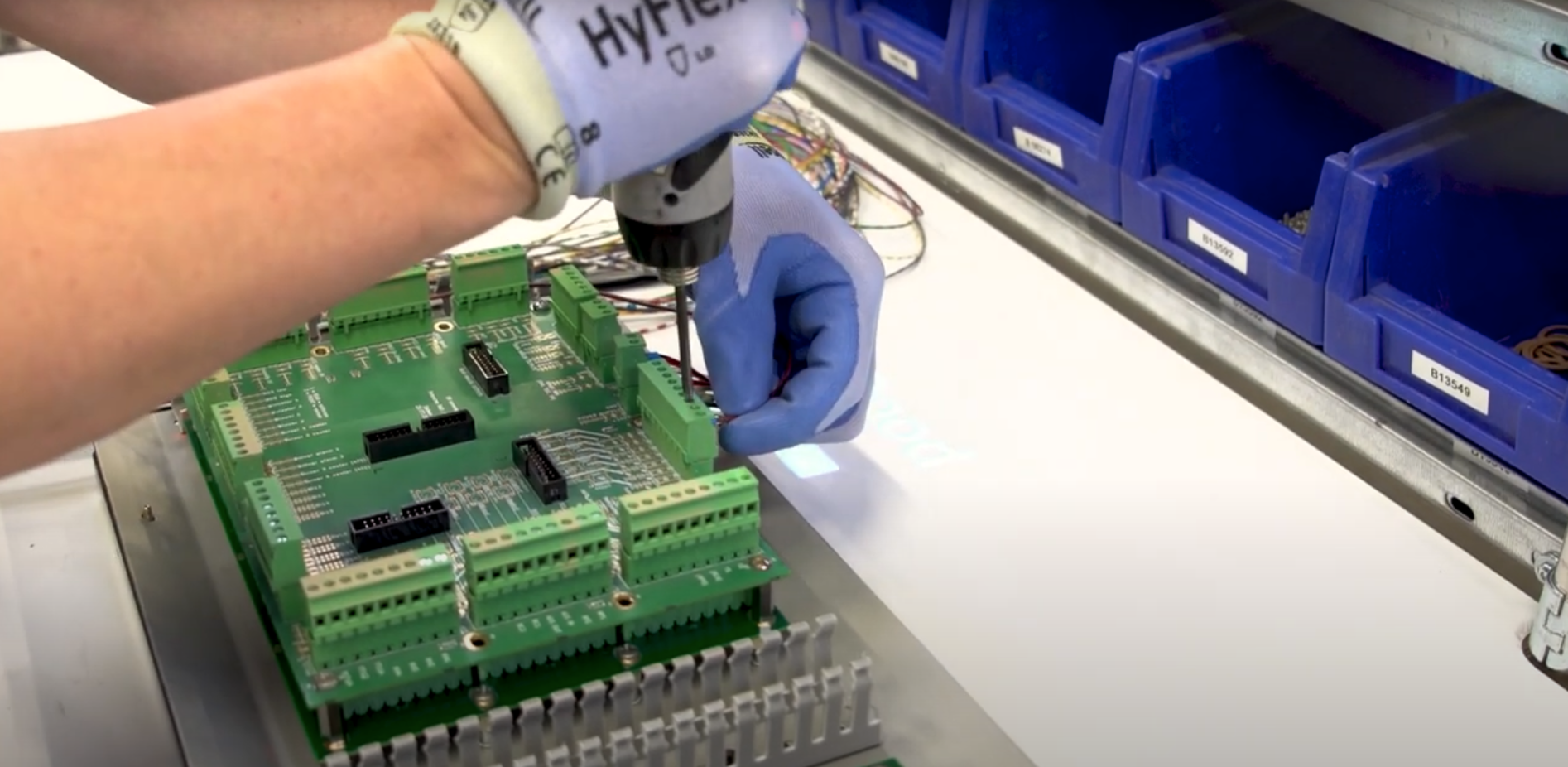

Guiding Operators at Webasto

- Guiding highly complex assembly tasks with augmented reality projections

- Validating the correct execution of these assembly tasks

- Integration with PLC

- Logging of relevant quality data

As world market leader in sunroof solutions, Webasto offers the broadest product range of high quality roof systems for automotive manufacturers. From large-area panorama roofs with versatile additional features, and classic sunroofs through to convertible roofs.

To improve the quality of the priming process of the sunroofs, Webasto used the Arkite platform to guide the operator with visual instructions. By integrating the Arkite workstation with the PLC, the operator gets custom instructions depending on the roof type. Arkite also validates the correct execution of priming and assembly tasks and ensures qualitative performance by preventing human errors. A virtual checklist is being generated to visually support the operator and to log relevant quality data per sunroof.

Arkite’s Operator Guidance platform transforms your manual workstations into a digital environment by deploying Augmented Reality.

It will give you the control and insights to efficiently steer and optimize your manual assembly processes.

Other solutions

Arkite’s Operator Guidance platform can help you find an answer to the challenges that arise in today’s highly competitive market. By deploying Augmented Reality on your factory floor, you transform your manual workstations into a digital and interactive environment that allows you to efficiently transfer knowledge to your operators. Thanks to the seamless integration in your company’s ecosystem, our platform will also provide you with the required information to optimize your assembly process.

Explore the details of our solutions, or click the contact button below to find out more.