Guiding increasingly complex assembly processes.

Dealing with complex assemblies through Operator Guidance

- Support customization and small batch production

- Process optimization through standardization

- Improve flexibility and productivity

- Allow for data-driven decision-making

Managing increased complexity in product assembly

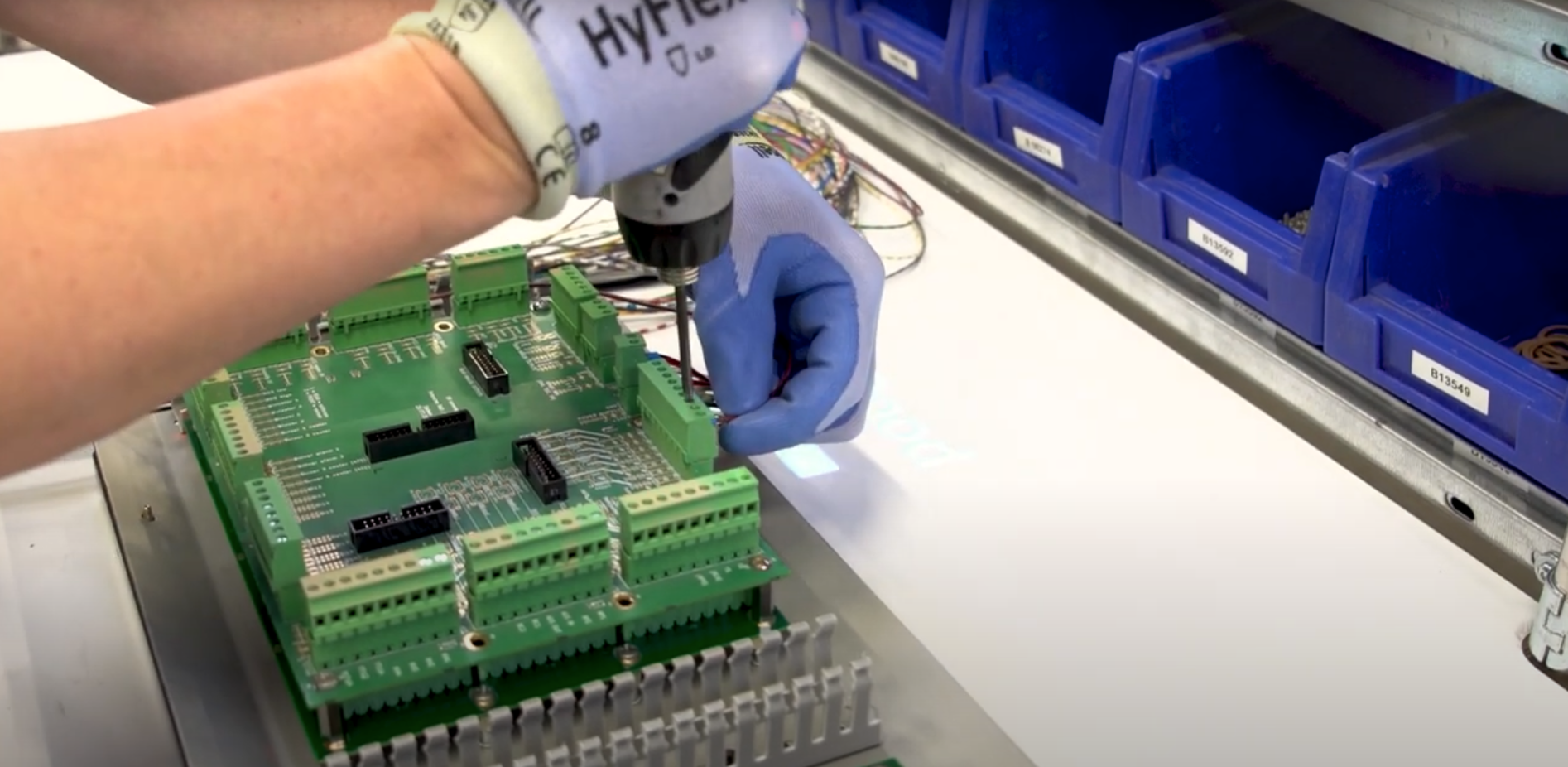

Manufacturing assembly processes have become increasingly complex with the rise of customization and small batch production. To keep up with these changes and maintain quality, process optimization through innovative technologies is crucial.

In this context, Arkite’s Operator Guidance platform helps manufacturers to increase their productivity and quality in their assembly. The platform provides interactive and clear step-by-step instructions that are easy to follow by operators. Through validation via its 3D sensor, the platform also ensures that procedures are applied correctly. This improves flexibility, productivity and quality throughout all stages of production.

Furthermore, the platform tracks and collects data in real-time, allowing manufacturers to gain valuable insights into their processes and make data-driven decisions to improve operations. It also allows for easy updating and distribution of procedures, and eliminates time-consuming editing and reviewing of instructions on paper or in PDF. This leads to improved traceability and allows manufacturers to have a better understanding of their processes and their efficiency.

In summary, Arkite’s Operator Guidance platform improves manufacturing assembly processes by providing interactive and clear operator guidance, 3D sensor validation, real-time data tracking, and easy updating and distribution of procedures.

Guiding Operators at Webasto

- Guiding highly complex assembly tasks with augmented reality projections

- Validating the correct execution of these assembly tasks

- Integration with PLC

- Logging of relevant quality data

As world market leader in sunroof solutions, Webasto offers the broadest product range of high quality roof systems for automotive manufacturers. From large-area panorama roofs with versatile additional features, and classic sunroofs through to convertible roofs.

To improve the quality of the priming process of the sunroofs, Webasto used the Arkite platform to guide the operator with visual instructions. By integrating the Arkite workstation with the PLC, the operator gets custom instructions depending on the roof type. Arkite also validates the correct execution of priming and assembly tasks and ensures qualitative performance by preventing human errors. A virtual checklist is being generated to visually support the operator and to log relevant quality data per sunroof.

Arkite’s Operator Guidance platform transforms your manual workstations into a digital environment by deploying Augmented Reality.

It will give you the control and insights to efficiently steer and optimize your manual assembly processes.

Other solutions

Arkite’s Operator Guidance platform can help you find an answer to the challenges that arise in today’s highly competitive market. By deploying Augmented Reality on your factory floor, you transform your manual workstations into a digital and interactive environment that allows you to efficiently transfer knowledge to your operators. Thanks to the seamless integration in your company’s ecosystem, our platform will also provide you with the required information to optimize your assembly process.

Explore the details of our solutions, or click the contact button below to find out more.

FLEXIBLE PRODUCTION

KNOWLEDGE PRESERVATION AND ONBOARDING

PAPERLESS WORK ENVIRONMENT

CABLING/WIRE HARNESSES

PICKING AND KITTING

TIGHTENING

TRACEABILITY

DATA INSIGHTS

STANDARDISED WORK

Improve your

manual operations

with better

consistency

and reliability

%

error reduction

%

rework reduction

%