Arkite’s approach for your workspaces.

Augmented Reality into your workplace

Arkite and our local certified partners are extending all necessary services including project management, training, documentation and engineering support to secure a seamless autonomation of manual workbenches, tailored to your specific industry. In short, we are very much ready to introduce Augmented Reality into your workplace.

Arkite’s approach for your workspaces

Industry 4.0 technologies are changing manufacturing.

Industry 4.0 is revolutionizing the way companies manufacture, improve and distribute products. Therefore, manufacturers across the globe are integrating new technologies into their production facilities and throughout their operations. These smart factories are equipped with advanced sensors, embedded software and robotics, not only guiding operators towards a well-controlled, standardized way of working but also collecting and analyzing relevant data for better decision making.

How to take full advantage of the Industry 4.0 premises?

As new digital technologies can lead to a higher level of efficiency and quality assurance, manufacturing plant managers need to carefully assess the tangible benefits of the innovations available. They need to understand how to introduce, integrate and deploy the newly available capabilities to their manufacturing plant, while securing a relatively short return on investment in today’s cash constraint business environment. Therefore, they should be able to count on the industry specific know-how and experiences of the ‘new technology supplier’, making sure they can justify and subsequently live up to business expectations.

Introducing Augmented Reality into your workplace.

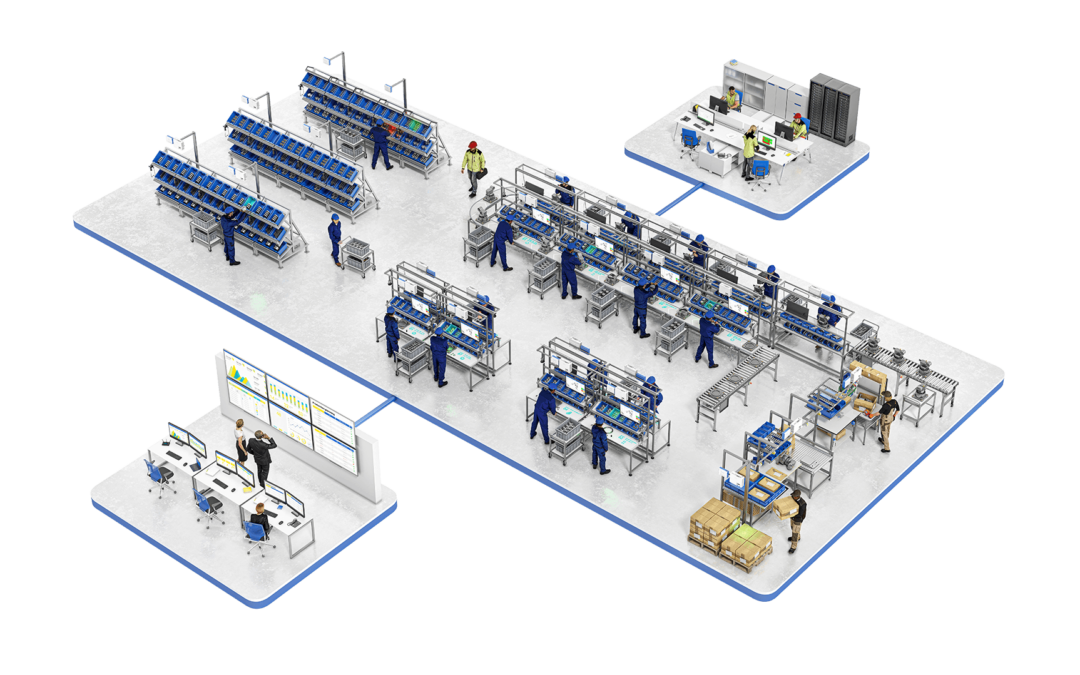

At Arkite we are on a mission to support customers throughout the process of introducing and successfully deploying our groundbreaking technology. We help management to identify and customize the most promising use cases for the deployment of augmented reality in to the manual workstations of their manufacturing plant(s) as a key enabler in their journey towards industry 4.0. In this respect Arkite has established a proven process, often in cooperation with our local certified partners, to jointly define expectations, scope, objectives (or Key Performance Indicators) as well as Key Success Factors to turn the innovation project into a resounding success for all stakeholders.

Getting our act together.

Taking the full benefit of Arkite’s solution for automating manual workstations and integrating those in the customer’s IT/ECO system requires the involvement of several key stakeholders throughout the process, including operations, quality, engineering, IT and management. After an initial Proof of Value related to the selected use case(s), project expectations and scoping need to be set, as we aim to standardize, streamline and integrate operational practices throughout the manufacturing plant. At regular times, relevant data collected need to be jointly analyzed, further improving the business return as well as the user experience.

Arkite and our local certified partners are extending all necessary services including project management, training, documentation and engineering support to secure a seamless autonomation of manual workbenches, tailored to your specific industry. In short, we are very much ready to introduce Augmented Reality into your workplace.

Arkite’s operator guidance platform

This Operator Guidance platform is:

- Smart by providing intelligent detections and process steps.

- Integrated with the factory IT Systems

- Contactless and easy to install, configure, use, maintain, adapt and scale…

Discover a wide range of innovative capabilities

The Arkite solution provides a wide range of innovative capabilities which allow operators to substantially improve their performance, while enabling management to continuously monitor and improve the manual processes applied.

Improve your

manual operations

with better

consistency

and reliability

%

error reduction

%

rework reduction

%

reduce training time

Learn more about Arkite

Digital Work Instructions in Manufacturing: From Paper SOPs to Guided Assembly

Digital Work Instructions in Manufacturing: From Paper SOPs to Guided Assembly Digital work instructions are becoming a foundational building block for modern manufacturing. As product complexity increases and experienced operators become harder to retain, paper-based...

5 challenges in production and how to solve them

In the dynamic world of manufacturing, challenges are as constant as change itself. But what if you could turn these challenges into opportunities? “5 Challenges in Production and How to Solve Them” is your guide to doing just that.

From Work Instructions to Operational Excellence with One Standardized Platform

Modern manufacturing demands more than just digital work instructions. It requires a fully integrated platform that enhances operator efficiency, quality assurance, and process standardization. Arkite’s Augmented Reality-powered Operator Guidance Platform goes beyond...