Projected Augmented Reality

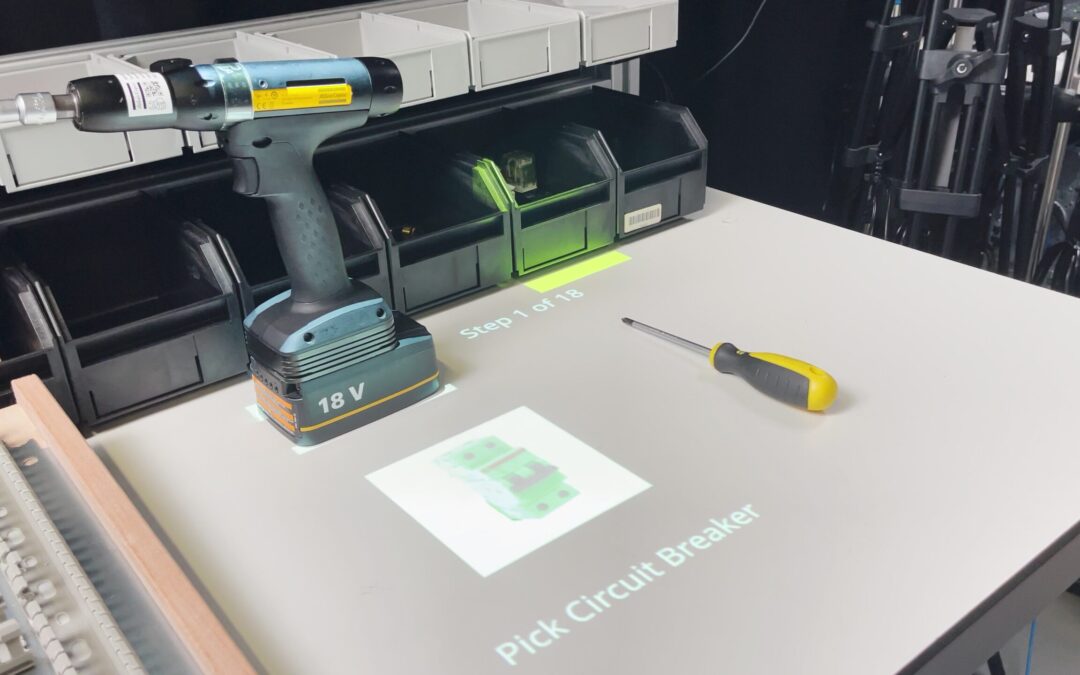

Digital Work Instructions replace traditional paper-based manuals with interactive, visual, and real-time guidance for operators. By delivering step-by-step instructions directly at the workstation, they standardize processes, reduce errors, and improve efficiency. These instructions are typically displayed on screens, tablets, or augmented reality systems, ensuring that every operator follows the correct procedure.

Why Choose for digital work instructions?

- Enhanced Clarity and Accessibility: DWIs replace cumbersome paper manuals with intuitive, interactive instructions, making it easier for operators to understand and follow complex processes.

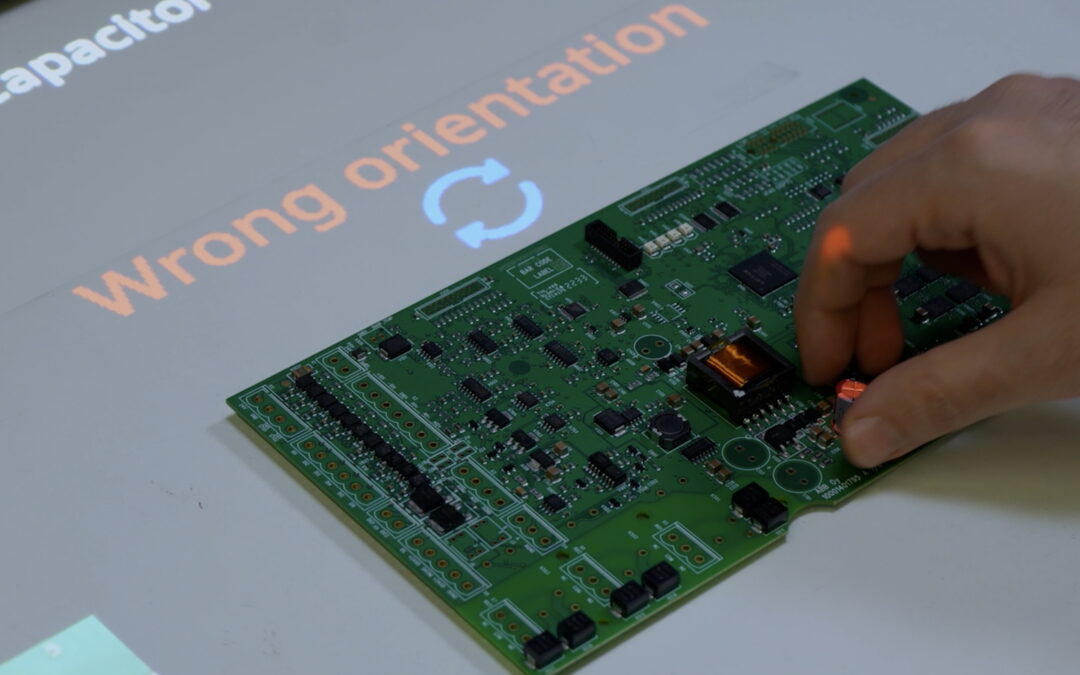

- Error Reduction: By providing real-time guidance and validation, DWIs significantly reduce human errors and rework rates.

- Faster Training: New operators can achieve proficiency quickly, minimizing the time and resources spent on training.

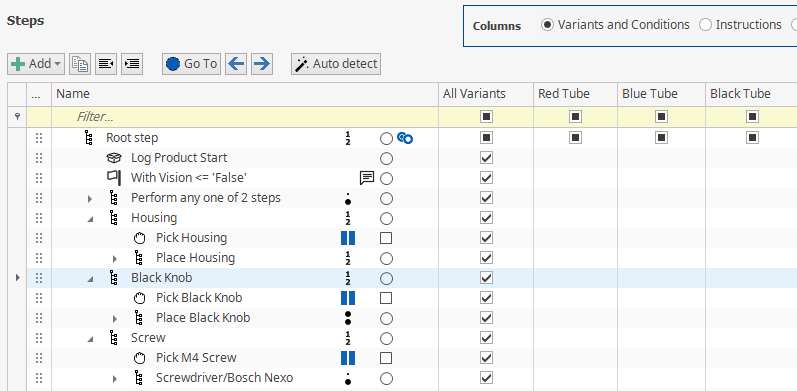

- Adaptability and Flexibility: Easily update instructions to accommodate product variations and process changes.

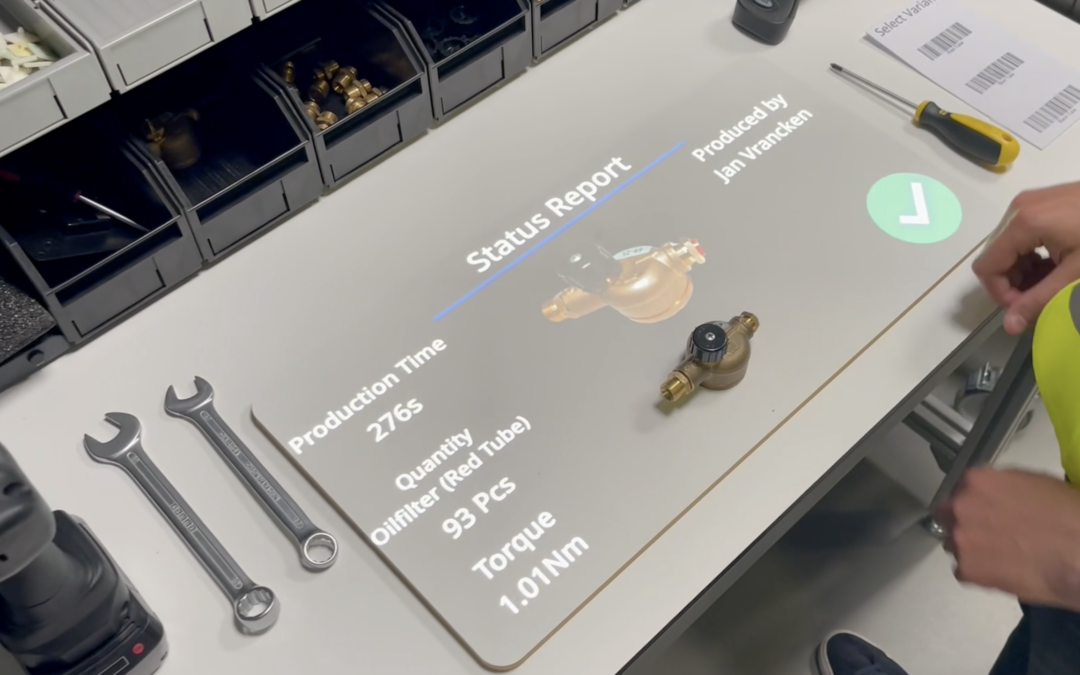

- Data-Driven Insights: Track performance metrics to identify bottlenecks and optimize processes.

PROJECTED AUGMENTED REALITY

CONTACLESS

No wearables, created for 24/7 production promoting safety and ergonomics.

REAL-TIME

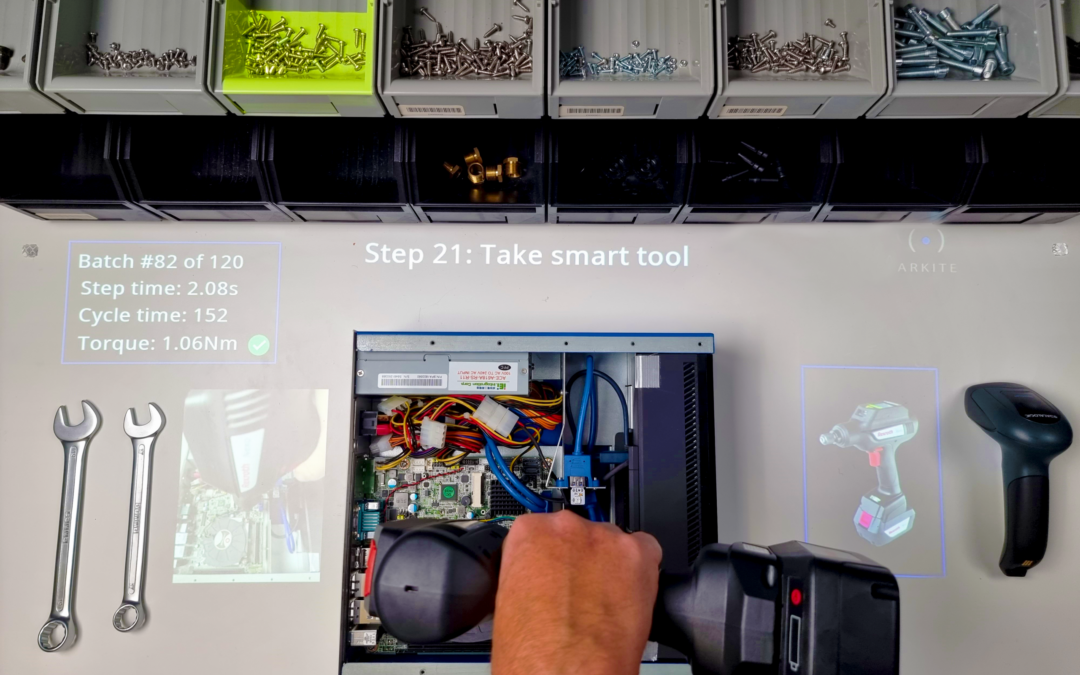

Instant guidance and feedback in the sight of eye ensures accurate task performance.

CUSTOMIZABLE

Tailor work instructions for specific tasks or operator needs or product variants.

INTUITIVE

Step-by-step visual guidance simplifies even complex procedures.

Tackle today's challenges in manufacturing with Projected Augmented Reality supported by Arkite’s Operator Guidance platform

By deploying Augmented Reality on your factory floor, you transform your manual workstations into a digital and interactive environment that allows you to efficiently transfer knowledge to your operators. Thanks to the seamless integration in your company’s ecosystem, our platform will also provide you with the required information to optimize your assembly process.

Explore the details of our solutions here:

Learn more about Projected Augmented Reality

Learn all about lean manufacturing, poka yoke, process validation and digital work instructions.

Arkite’s operator guidance platform

This Operator Guidance platform is:

- Smart by providing intelligent detections and process steps.

- Integrated with the factory IT Systems

- Contactless and easy to install, configure, use, maintain, adapt and scale…

The Arkite solution provides a wide range of innovative capabilities which allow operators to substantially improve their performance, while enabling management to continuously monitor and improve the manual processes applied.