Lean Manufacturing, 5S, SixSigma… they all refer to manufacturing philosophies aimed at optimizing production processes by increasing efficiency and eliminating scrap, rework, and waste of time or resources.

Some of the main principles that are applied in these methods are:

- Remove objects, tools and parts that are not required in the assembly process from the work environment

- Make sure that all remaining objects, tools and parts have a fixed location, are easily accessible and can be easily found at all times

- Ensure the work environment is clean and free of dirt at all times

- Eliminate all safety hazards

- Maintain all actions above by training your staff and creating checklists

- Standardize your work environment.

This not only refers to providing tools and procedures to ensure the actions above are duly implemented and maintained. It also includes creating standard operating procedures that document how and in which sequence assembly processes are executed.

All of the principles above are quite logical and easy to understand. Bringing them into practice is more complicated. The hardest part is making sure that your complete staff understand and abide with the procedures you put in place to maintain them.

Therefore, it is of key importance to translate your standard operating procedures into practical work instructions that are easy to understand and leave no room for confusion.

In this blog post, we will focus on achieving a standardized work environment and creating the required work instructions to maintain it. We will also explain you how the Arkite’s operator guidance platform can support you in this task.

Why is a standardized work environment important?

Before explaining how to achieve a standardized work environment, let’s first list why we want and need this standardized work environment:

- Breaking up your assembly process into small steps and defining a fixed sequence will enable you to find the optimal and most efficient way of working. Each step can be timed and it is easy to make adjustments if needed.

- Steps leading to excessive delays and errors can be identified

- Giving all tools and parts a fixed location on your workbench makes your assembly station a clean and safe place. Furthermore, no time will be wasted due to lost or misplaced items.

- Training of new employees is faster and can be done more efficiently

- Temporary workforce can be engaged more quickly into the assembly process

- It is easier for operators to switch between different assembly stations and processes

- Standardized processes lead to predictability and therefore a better inventory management

What aspects are important in achieving a standardized work environment?

In order to achieve a standardized work environment, you need to:

- standardize your assembly process:

make sure all operators perform the assembly process in the same order, with the same tools and the same result - standardize your workbenches:

make sure the workbench looks the same at all times. Tools and parts should have the same location, no redundant items should be present.

Operators won’t loose any time looking for tools or parts when taking over a shift or performing the assembly at a different station - standardize your work instructions:

make sure that every step in your assembly process is documented in the same way, through easy-to-understand work instructions that leave no room for confusion.

How to write standardized work instructions?

It may sound easy to write standardized work instructions, but in practice it proves to be not that self-evident. Therefore we want to elaborate on the characteristics you should take into account when writing good work instructions:

- Be concrete:

Describe precisely what needs to be done. Don’t be vague or leave room for confusion or interpretation. - Be brief:

Keep your work instructions as short as possible. Avoid information that is superfluous and adjectives or adverbs that do not contribute to a better understanding. - Be comprehensive:

Describe each and every step in the assembly process. Don’t miss any details. Don’t assume steps are evident. This is a common pitfall when documenting processes you know very well yourself. Let someone that has less or no experience review your instructions to make sure nothing is forgotten. - Be consistent:

Describe every instruction in the same manner. Use the same terminology throughout all of your instructions. Use the same layout and word order across instructions. - Be simple:

Keep the language you use as simple as possible. Avoid using passive voice, difficult terminology and complex grammatical constructions. Where possible, use the imperative form – you are giving instructions, no need to be polite. - Be accurate:

Ensure your work instruction exactly matches the task that needs to be executed and is in line with operator’s work environment. - Be accessible:

Make sure operators can easily find the appropriate work instruction for the task they are performing an that they can access the instruction while executing the task. - Be visual:

Add pictures or videos to your work instructions. Research shows people process visual information 60,000 times faster than textual information.

A closer look at how Arkite’s Operator Guidance Platform helps you in achieving and maintaining a standardized work environment

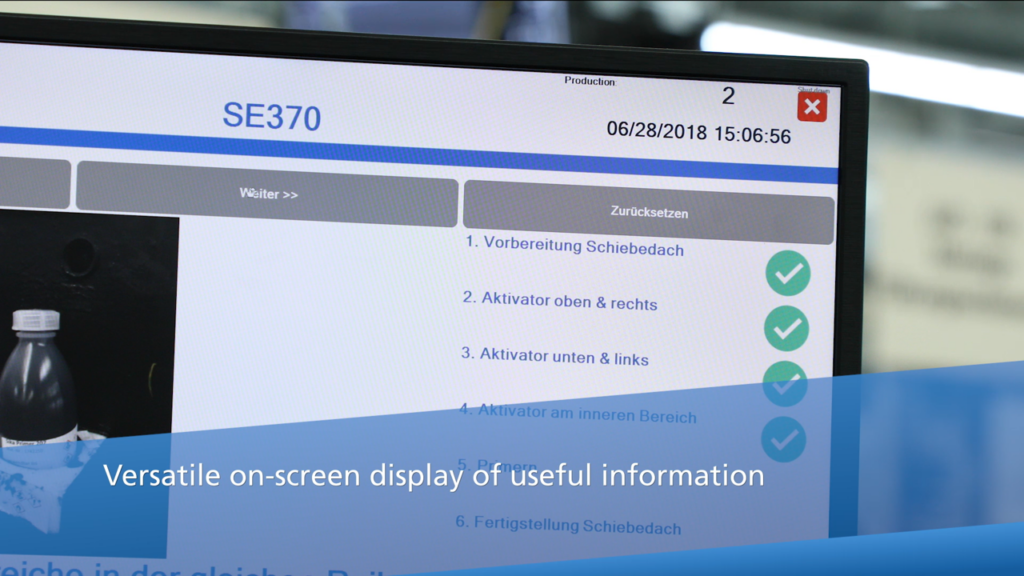

Arkite’s Operator Guidance Platform transforms workstations into a digital and interactive environment. It translates and breaks down your standard operating procedures into distinct, small assembly steps. By means of its integrated Time of Flight sensor, it detects the tools, picking bins and parts on your work bench as well as the activities performed by the operator. At the same time, it guides yours operator through the assembly process by providing them real-time picking and assembly instructions by means of projected Augmented Reality. The platform also validates whether actions have been executed correctly and warns your operators upfront when they are about to make an error.

As such, Arkite’s Operator Guidance Platform is a great help for you to achieve and maintain a standardized work environment.

First of all, it helps you to standardize your workbench:

- At the start of the process, the platform verifies if all required parts and tools are present a their expected location. If that is not the case, the operator can simply not start process when not everything is in its place

- During the assembly process, operators are instructed to put the tool back after use (and cannot continue if they don’t)

- If at any point in the process, a tool or object is not at its expected location, an error is projected on the workbench

The platform also helps you to standardize your assembly process:

- By breaking down your assembly processes in small sequences, it makes your standard operating procedures explicit and ensures they are always executed in the same order

- Every step of the assembly process is validated. Only after confirmation, the operator can continue with the next action.

- Smart tools only work when and where they are supposed to be used

Finally, the platform also helps you to write good and standardized work instructions:

- Instructions are always projected at the same location on the workbench, ensuring consistency.

- There is a limited amount of place available for instructions, encouraging brevity and simplicity.

- Each instruction is linked to a specific step in your process and is projected at time it must be executed, ensuring both comprehensiveness and accessibility.

- The platform also supports projecting image and video instructions, allowing to present information visually.

Interested in seeing Arkite’s Operator Guidance Platform in action? Have a look at our references and case studies. For more information, contact info@arkite.com